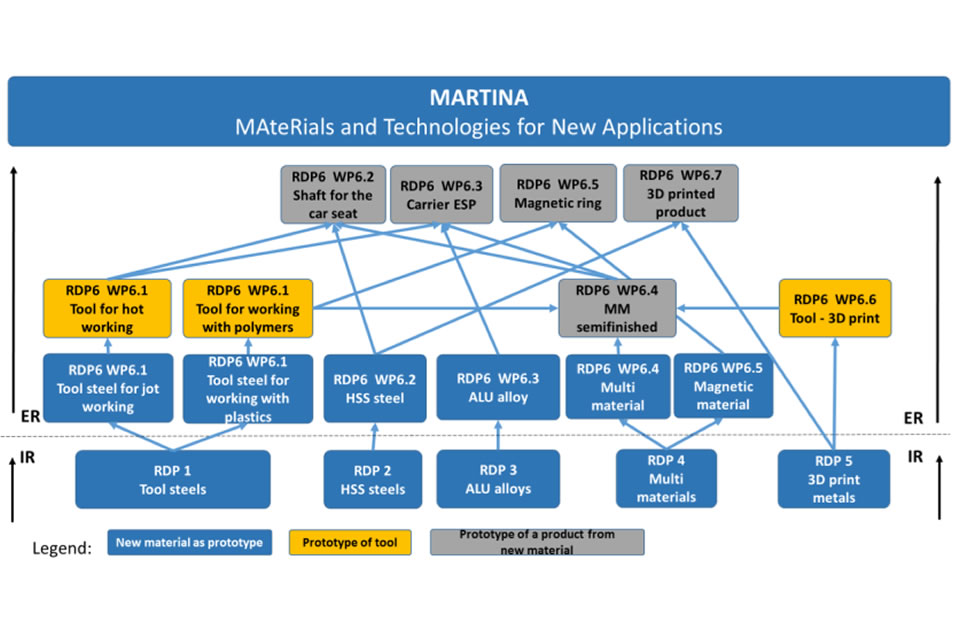

The MARTINA program consists of six research development projects (RRPs), which are interconnected and together contribute to the realization of the vision of the program

- RRP1– Advanced tool steels for innovative tools of new generation

- RRP 2– New high strength steels

- RRP 3– Advanced aluminium alloys with improved properties

- RRP 4– Multicomponent materials, thermoset and thermoplastic composites

- RRP 5 – AM, 3D printing and innovative materials manufacturing technologies for end use

- RRP 6– Development of prototypes

RRP1 – Advanced tool steels for innovative tools of new generation

RDP1 focuses on research in the field of novel, advanced materials that are used to manufacture tools for the metal industry and will be used in the ER phase to develop a prototype of a new tool steel and from this develop innovative tools of the next generation. This relates to tool steels that have special requirements and specific properties for their usage. A type of tool steel developed in this RDP is, for example, tool steels for hot work and steels for the working with plastic. Special attention will be given to possibilities for better material properties (heat conductivity, temperature stability, resistance to heat and mechanical fatigue, heat properties and surface treatments), as well as functional properties (gradient properties, compatibility with other materials and welding) of tool steels and hot-work steels. There are also more and more demanding requirements in the field of tool steels for the production of tools for cold work and the injection of plastic.

RRP 2 – New high-strength steels

RDP2 is focused on research in the field of high-strength steels, their production and processing technologies. Modern trends in the automotive industry require the use of light-weight materials, and reduction in the weight of components, thereby reducing the fuel consumption and the CO2 footprint. Reducing the weight requires an improvement of the mechanical properties of the materials being used. The construction of the car itself requires a very diverse mix of materials with different properties.

RRP 3 – Advanced aluminium alloys with improved properties

RDP3 is dedicated to research in the field of aluminium alloys for the automotive industry with the emphasis on achieving better mechanical properties. Aluminium and aluminium alloys represent some of technically most interesting materials. Due to its characteristics, aluminium is used for everyday products as well as for demanding industrial products. The use of aluminium and its alloys in so-called lightweight structures is gaining importance due to energy savings and reduction of environmental impact.

RRP 4 – Multicomponent materials, termoset and thermoplastic composites

Multicomponent materials of thermoplastic or thermosetting polymer composition, such as polymer composites from the macro/micro/the nano polymer blends, multilayer hybrid assemblies, plastomagnets bonded with a thermoset binder, have emerged as a new class of materials representing technological breakthroughs in many different industrial fields: advanced packaging in cosmetic, phamaceutical and food industry, bonding and matrix components in textile and automotive industry, home appliances, biomedicine, itd. The development of advanced multi-component polymer materials is driven by the ability to combine different polymers, layers, components or additives so as to achieve a synergistic effect of individual components in final products with improved functionality. The major market demands for innovative mateirals imply new material alternatives that will contribute to lightweight products, physical, mechanical and thermal property enhancements, flame retarding properties, UV resistance, reduced permeability to gases, moisture, and hydrocarbons, shrinkage and warpage deflections, self-cleaning abilities, antimicrobial activities ferromagnetic properties, electrical conductivity, and others.

RRP 5 – AM, 3D printing and innovative materials manufacturing technologies for end use

RDP5 is focused on research in the field of advanced technologies for materials processing for different applications. The two main fields of application are AM,”additive manufacturing” and the 3D printing of metal powders and a less investigated research area. In recent years, 3D printing has become a common fabrication method and a good practice for manufacturing of complex industrial components. Despite this, the 3D printing of metals addresses a lot of unknowns, yet a lot of opportunities offered by these new technologies and materials, especially in combination of various metal and non-metal materials.

RRP 6 – Development of prototypes

RDP6 is the only project among the six of them in the program, which is planned for experimental development and includes as its main activity the preparation and development of prototypes, as well as their analysis and testing in controlled environments in the main areas of the program as a results of the activities of industrial research in RDP1-RDP5. Prototypes in the project will be modelled and developed on the basis of the results of industrial research, obtained knowledge, analytical and test reports, engineering recommendations, specifications of new chemical compositions of materials as well as specifications and models of technological processes in manufacturing and processing of new materials and other results.

More: www.martina-eu.net