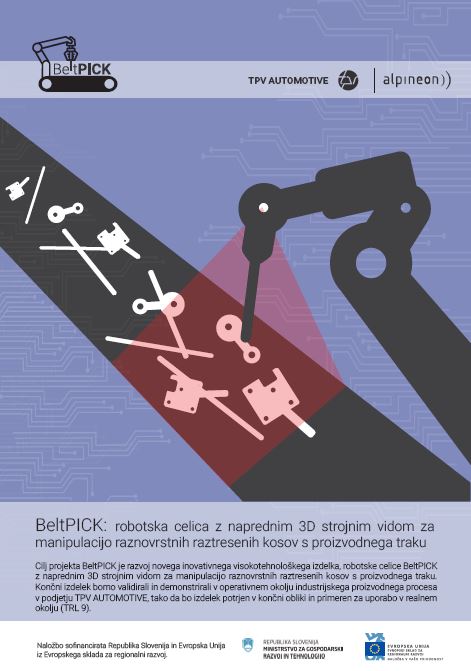

Robotic cell with advanced 3D machine vision for manipulating a variety of scattered pieces from the production line.

The BeltPICK project joins strengths of large-scale production company TPV and hi-tech SME Alpineon, focusing on breakthrough innovation for automated factories of the future.

In the framework of the project, we developed a BeltPICK robot cell equipped with advanced 3D machine vision for handling scattered parts on the production line (belt). The final product was validated and presented in the operational environment of an industrial production process running at the project’s main partner, so that the product was approved in its final form and suitable for use in a real industrial environment (TRL 9).

The process of picking products scattered on the entry conveyor belt and their correct positioning was made by a robotic arm with an interchangeable gripper and by using innovative 3D bin picking techniques which was be developed on the basis of RDI project RoBIN findings and our own patented solutions upgraded and optimized within this project.

The project generated many new breakthrough solutions representing technical progress. The development aimed at reaching a universal system capable of picking and positioning many types of products of various shapes on the entry conveyor belt, which represented a key competitive advantage of the BeltPICK robot cell.

The development of the BeltPICK robot cell took place in several R&D stages. It consisted of activities in the form of industrial research and experimental development performed at technological stages TRL 4 – 9, and other supporting activities. The project activities were performed according to the principle of concurrent engineering. The final product was validated as a pilot and operational product in the automotive industry, and further on we will, together with our partners, transfer its application to other business sectors.

The project was partially co-financed by the Republic of Slovenia, i.e. The Ministry of Economic Development and Technology and the European Union, i.e. the European Regional Development Fund (ERDF). TPV AUTOMOTIVE was the leading partner, and in the development of the machine vision system, the supporting partner was the company ALPINEON d.o.o., which is also our development partner on other similar projects.

Project duration: 24 months

Start of the project: July 9, 2020

End of the project: July 8, 2022

Project value: EUR 848,663.60

Co-financing value: EUR 298,867.75